Electric Choke Wiring Diagrams are essential tools for anyone working on electrical systems in vehicles. These diagrams provide a visual representation of the electrical connections and components involved in an electric choke system, making it easier to understand and troubleshoot any issues that may arise.

Why Electric Choke Wiring Diagrams are Essential:

Electric Choke Wiring Diagrams are essential for several reasons:

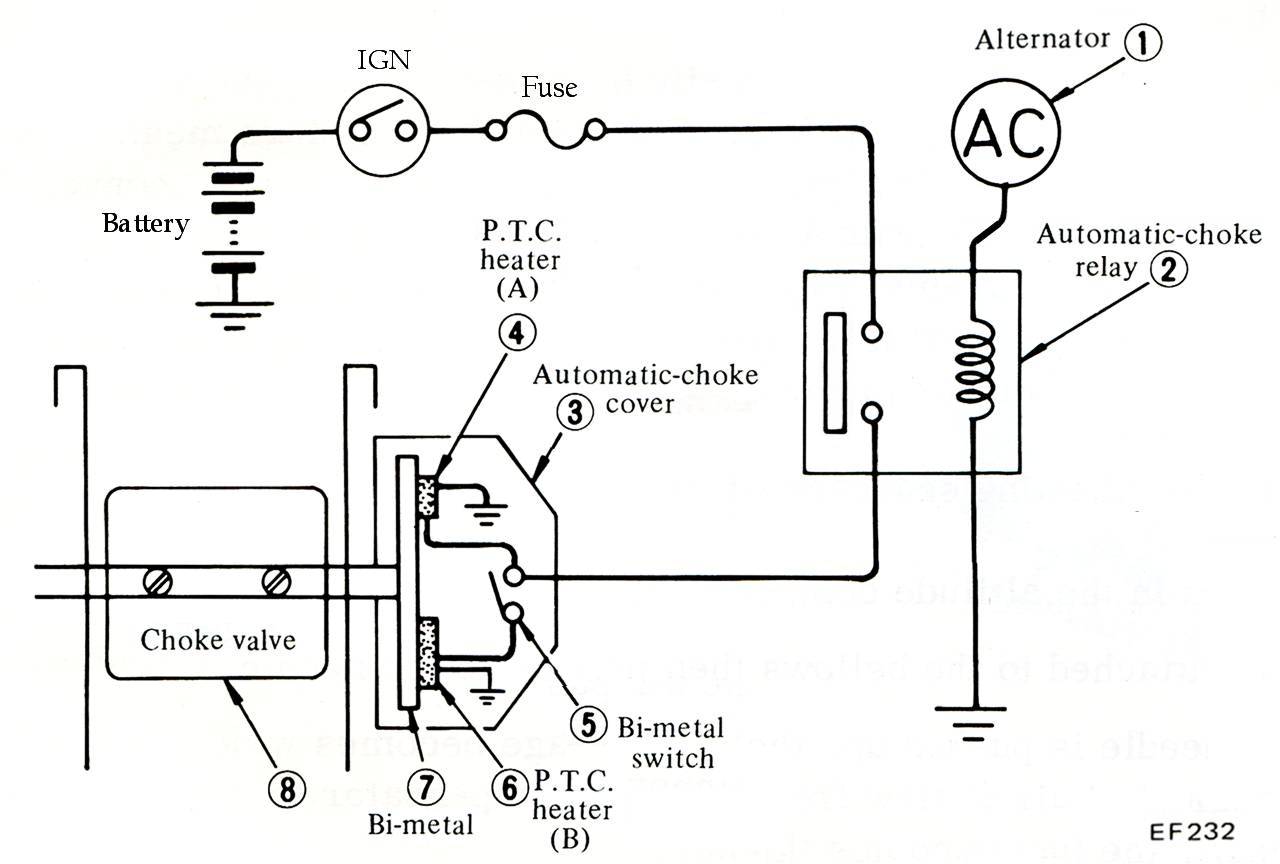

- They outline the electrical connections and components of the electric choke system.

- They help identify the location of key components within the system.

- They provide a visual reference for proper installation and troubleshooting.

How to Read and Interpret Electric Choke Wiring Diagrams:

Reading and interpreting Electric Choke Wiring Diagrams effectively requires attention to detail and a basic understanding of electrical systems. Here are some key points to keep in mind:

- Identify the key components of the electric choke system, such as the choke coil, relay, and wiring harness.

- Follow the lines and symbols on the diagram to trace the electrical connections between components.

- Refer to the legend or key provided with the diagram to understand the meaning of different symbols and colors used.

Using Electric Choke Wiring Diagrams for Troubleshooting:

Electric Choke Wiring Diagrams can be invaluable tools for troubleshooting electrical problems in vehicles. By following the wiring diagram, you can:

- Identify potential issues with the electrical connections or components in the system.

- Check for continuity and proper voltage levels at key points in the system.

- Compare the actual wiring in the vehicle to the diagram to pinpoint any discrepancies that may be causing problems.

Importance of Safety:

When working with electrical systems and using wiring diagrams, safety should always be a top priority. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical systems to prevent the risk of electrical shock.

- Use insulated tools and wear proper protective gear, such as gloves and safety glasses, when handling electrical components.

- Double-check all connections and wiring before re-energizing the system to avoid short circuits or other potential hazards.

Electric Choke Wiring Diagram

Edelbrock Electric Choke Wiring Diagram

How to Wire a Relay for an Electronic Choke – YouTube

Step By Step – Chrysler 440 Six Pack Electric Choke – Hot Rod Network

Electric Choke Wiring Diagram Ford F100

Edelbrock Electric Choke Wiring Diagram

Electric Choke Wiring Diagram Webber – Good Stray Cat Trap